Rayon Fabric and Interfacing Placement

Interfacing is the back bone for garment construction. When placed in the wrong direction, it can make the garment look less than professional.

1. Rayon and other drapey fabrics has a tendency to relax (stretch) vertically when worn.

2. Pre-shrink all woven, weft insertion, or stretch interfacings. Be sure to handle your fusible interfacings gently. To pre-shrink, place the interfacing in a sink full of hot water and let sit for 15-20 minutes (until water cools). Drain and roll the interfacing in a towel to remove excess water. Hang woven interfacing to dry over a shower rod with the glue side up. Lay knit interfacings flat to dry to avoid stretching out of shape.

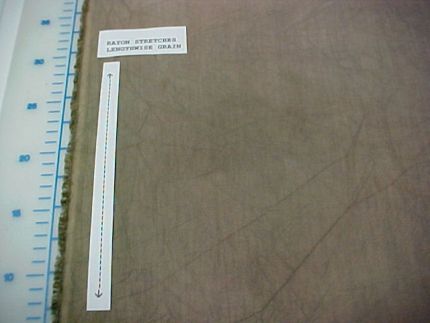

The pattern placement on the interfacing is critical. Choose an interfacing that has crosswise stretch. On the facing pattern piece, check to see which way the grain line is drawn. Place the pattern in the same direction the interfacing stretches, which is crossgrain–or perpedicular to the grainline.

When the interfacing is fused to the fashion fabric, and then worn, the interfaced section of the garment will move the same way the rest of the garment that is not interfaced, moves.

If the interfacing is fused the ‘old fashion way’, lengthwise (without stretch), the fashion fabric/interfacing becomes static. If buttonholes are sewn along a vertical section of the garment, the fabric has a tendency to ‘lop’ over the buttonhole and the hem will drape down once it has passed the static facing.

Start your 14-day FREE trial to access this story.

Start your FREE trial today and get instant access to this article plus access to all Threads Insider content.

Start Your Free TrialAlready an Insider? Log in

Thank you for this information; I am about to buy a bunch of rayon fabric which is on sale, and this is a good timely tip iun case T end up interfacing some of it!!

This was wonderful information. I didn't know you should and could preshrink fusible interfacing. I have several pieces of rayon and other stretchy fabrics on which I will use this method.

This information is quite interesting. However, I too did not know that you can wash fusible interfacing.

This now explains why my rayon dress with buttons and buttonholes down the entire front is droopy and loopy. Wish I had seen this sooner. It is not pretty

Great tip. Thank you for posting it. I just bought some rayon for summer blouses so I'm going to follow these directions for the button plackets.

63 years old, and sewing since I was 9................Learned something new today, and I wish I would have learned it sooner. I ADORE rayon, and this all makes sense now.

I guess you are never to old to learn.....BRAVO!

I have also heard (and done) that you can hover a steam iron over the fusible and that will also shrink it. I wonder if that is true or if the washing is the only true way to preshrink the interfacing. I did not know to place the fusible crosswise and my result was less than professional. It was for a one time flower girl dress so..not that critical for the long haul.

Thanks for your always great advice.

Now if only this had been posted two weeks ago! Just made my first blouse with rayon. For next time...

Glad to know this as I am about to start sewing with rayon for skirts and blouses. Thank you!

This is a good reminder; I learned this earlier, but had totally forgotten. I also plan to sew with rayon very soon and will make sure the front plackets are interfaced correctly. Thanks for all your great advice.

This is a good reminder; I learned this earlier, but had totally forgotten. I also plan to sew with rayon very soon and will make sure the front plackets are interfaced correctly. Thanks for all your great advice.

Someone at threads went to the trouble to print paper labels to place on the fabric pieces shown on the cutting mat. What, please, do they say? If I enlarge the photo, the printing becomes a blur. Thanks for your time and the information.

This is great! Thanks for posting. Rayon is a tricky fabric to work with so the more helpful hints and tricks, the better.

Thank you so much for posting this. I am getting ready to work with alot of rayon.

Sewing Isalnder, I too just learned we should pre-shrink fusible interfacing. any suggestions on how to best pre-shrink it?

In step 2 it has the 'how to's' when working with interfacing...To pre-shrink, place the interfacing in a sink full of hot water and let sit for 15-20 minutes (until water cools). Drain and roll the interfacing in a towel to remove excess water. Hang woven interfacing to dry over a shower rod with the glue side up. Lay knit interfacings flat to dry to avoid stretching out of shape.

I only recommend woven or knitted interfacings for garment sewing. I don't work with any non-woven interfacing...it doesn't like to move the way knitted or woven interfacing do when fused to fashion fabrics.

I see there were a few comments that used the term 'wash' the interfacing...you just place the folded interfacing in hot water...you want to be careful when working with wet interfacing.

Sorry the wording is tiny on your computer...Rayon stretches lengthwise (parallel) to the edge of the fabric...when working with your pattern piece on the interfacing, place the facing pattern piece so it goes across the interfacing from edge to edge the way the interfacing stretches. This way it will stretch the same way the rayon fabric does once it is pressed into position.

Wow,

This is great information I love, love, love rayon fabric!

Does anyone have suggestions on where to find nice rayon preferably online as I live in the western foothills of Maine and stores are few and far between!!

Here is "a blast from the past." I'm a senior citizen, but still kicking. Before today's wide array of interfacings were created, I had satisfactory results simply by cutting interfacing pattern pieces out of the same fabric. I believe this would work well for challis. It would give you garment compatible added body, without employing crispness.

I lay the long straight, raw edge of such "self-interfacing" in the button-hole area, right sides together, atop and aligned at the fashion fabric's center fold line, with shaped (or outer edges together), then stitch the shaped edges together, using no wider than a 1/4" seam allowance. Clip to stitching line in curved areas.Turn and press the sewn sides flat.

Align the straight raw edge of the interfacing exactly at the front fold line and baste it in place on a line, then press the two layers in place, using a press cloth if style will have a folded-back lapel (to avoid a possible shine).

I'm terribly sorry, but much of what has been said here is way over my head! I'm not a novice, but have never, to my knowledge, worked with rayon, and have never really understood, before today, that different types of interfacing is needed, not just different weights. Coming from a rather low-income background, my experience is more with non-woven iron-on interfacing and polyester or cotton, or poly-cotton fabrics. So, all that being said as background, am I understanding correctly that the interfacing used for rayon fabric needs to be cut out on the cross-grain, whilst the fashion fabric is cut on the lengthwise grain? I understand pre-shrinking--something I've never done with interfacing, but now realize that having known to do so would've made such a difference in some of the garments I've made! At 56 years of age, I feel like I have so far to go before I can move up from "intermediate" to "advanced," and this is an area that will make a world of difference in the appearance of my garments. Sadly, I do not have anyone to teach me this in my little corner of the world, so all that I learn, I learn from Threads & craftsy.com!

While this information is very helpful, I am still a bit confused. I have a piece of "rayon woven" fabric. It has about a 20-25% stretch with the crossgrain, but no lengthwise stretch.. if I am saying that correctly. From selvage to selvage it stretches, and reoovers, 20 - 25%. No stretch from end to end of fabric length. Do I treat it as a knit? Ball point or stretch needle? Stretch stitch? What about thread? I plan on using sew-in interfacing and like the feel/weight of cotton lawn behind this fabric, but don't know if it is appropriate. The design will be a slightly loose fit top with front button placket and mandarin collar. Any suggestions would be much appreciated. Right now, the more I read, the more confused I become. Thank you. Susan