Q: What is the difference between nap and pile when you’re describing a fabric’s texture? Do you have to treat fabrics differently depending on whether they have nap or pile? Must you use a “with-nap” layout for pile fabrics?

—Robbie Easton, Champaign, Illinois

A: Threads Senior Technical Editor Carol J. Fresia teases out the distinction: Both words are used to describe a fuzzy fabric surface, and are often used interchangeably. However, they are not synonymous. Plushy fabrics are made in different ways, and it can be helpful to understand the distinction.

Napped fabric is made through the process of napping, also called raising or brushing. The surface of a flat woven or knit textile is treated with brushes to create a soft, fuzzy texture. Familiar examples include flannel, moleskin, and polar fleece. In most cases, the fabric’s weave includes some loosely twisted yarns, which are broken and fluffed by the brushes, creating the nap. The brushes may have wire bristles, but for delicate, fine wool and fibers such as cashmere, the fabric is brushed with the dried pods of the teasel plant, which have stiff bristles. (The words “teasel” and “tease” both come from a Middle English word meaning “to comb” or “to shred.”) Raising abrades the surface and can affect the fabric’s durability and wear patterns.

Fabrics made of long staple fibers, such as wool and mohair, can have a nap that is almost furlike in appearance. A napped finish tends to have a clear “direction of view,” which is referred to as “nap” in pattern layouts. A withnap layout takes this into consideration, so all garment sections appear the same color.

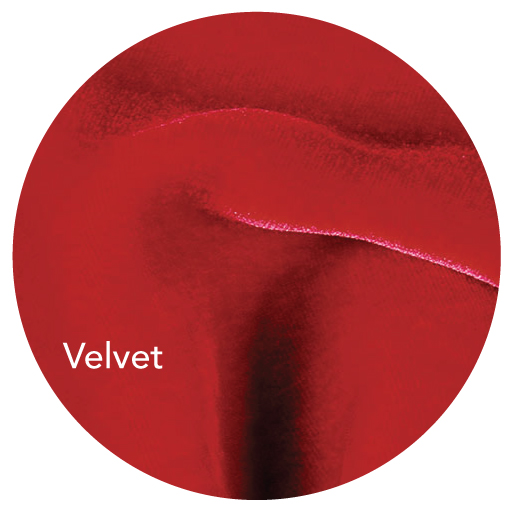

Like napped fabrics, pile fabrics also have fuzzy fibers on the surface. However, in pile textiles, these fibers are part of the textile’s weave or knit structure. Additional warp or weft yarns are incorporated into the fabric matrix, as in velvet. Looped yarns may be cut and then further brushed, as in corduroy or sheared terry. Faux fur fabrics, with short or long pile, may be woven, knitted, tufted (pile yarns are inserted into a backing fabric with needles), or stitch-bonded (pile fibers are sewn to a backing with a special machine). Like napped fabrics, pile fabrics typically have a pronounced directional appearance and should be cut using a with-nap layout.

This article was originally featured in the Q&A department of Threads #209 (June/July 2020).

Do you have a question? Send it to us and we’ll find an expert’s answer.

via mail: Threads Q&A, PO Box 5506, Newtown, CT 06470-5506

via email: ThreadsQ&[email protected]

via the Contact the staff page to submit your entry

Log in or create an account to post a comment.

Sign up Log in