Q: My sewing machine has an automatic needle threader. I’ve read the manual and followed the directions for using it, but it has never worked for me. Could it be broken, and if so, is there a way to repair it?

—Frances Williams, via email

A: Bernie Tobisch, author of You and Your Sewing Machine (C&T Publishing, 2018), explains how this handy feature should work, and why it sometimes fails to: An automatic needle threader is wonderful when it works but frustrating when it doesn’t. Understanding how it functions can help you diagnose the possible problem.

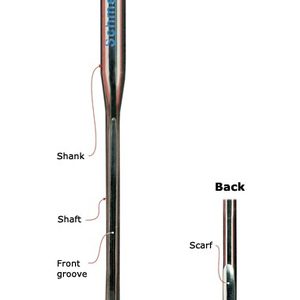

Some threaders have you position the thread and then move and release a lever. Others are fully automated—lay the thread in place, and push a button. The basic mechanism is otherwise the same. A small wire hook passes through the needle’s eye from back to front, grabs the thread, and pulls it back through the eye. It’s a simple concept, but things can go wrong. Try these tips for success.

Check the needle position

Make sure the needle eye is at the correct level for the wire hook to pass through it. If your machine has a needle up/down button, push it to position the needle in its full “up” position. Otherwise, use the handwheel to bring the needle to its highest position. If the needle is not fully up, the threader’s hook hits the needle instead of passing through the eye, and the hook bends to one side. It’s possible that the first time the threader was used, the wire hook was bent. Some machines automatically position the needle correctly as soon as the threader is activated.

Avoid threading tiny needles

In most cases, a needle smaller than size 70/10 has an eye that’s too small to accommodate the hook. More than likely, it will catch and be damaged. It may also scratch the inside of the needle’s eye, leading to stitching problems if the thread no longer moves smoothly through the eye.

Use with appropriate thread

Use garment construction thread, and match the thread size to the needle. You can’t pull a thick thread through a thin needle. Avoid using the threader with metallic or stiff threads. They can damage the threader’s hook.

Release the thread

Unless your threader is totally automated, remember to let go of the thread as soon as the hook has started to pull it through the eye. It may take practice to get the timing just right, but it’s important to avoid applying tension to the thread as the hook is pulling it. This can harm the hook.

If you have tried these tips and your threader still does not work, you might have to take the machine to the shop. Sometimes, the hook can be bent back into position but, in some cases, the threader head might have to be replaced.

Once the threader has been fixed, follow these hints to keep it working properly and to maintain a happy relationship with your machine.

This article was originally featured in the Q&A department of Threads #211 (October/November 2020).

Do you have a question? Send it to us and we’ll find an expert’s answer.

via mail: Threads Q&A, PO Box 5506, Newtown, CT 06470-5506

via email: ThreadsQ&[email protected]

via the Contact the staff page to submit your entry

Log in or create an account to post a comment.

Sign up Log in