All About Sewing Industry Seam Allowances

How and why patternmakers apply varied widths to designs

Most commercial patterns are drafted with a consistent seam allowance width along every seamline. It might be 1/4 inch in patterns designed for knits, or it could be 5/8 inch, the standard used in the majority of garment patterns drafted for woven fabrics. It appears convenient to work with the same seam allowance width throughout a garment: You can set the needle position relative to the desired seam guide and simply follow along for each seam.

However, all seams are not equal, and they don’t all need the same allowance. Consider that you typically trim most of the allowance at enclosed areas, such as along facing seams, or you occasionally need to let a garment out along a side seam. In these cases, narrower or wider allowances facilitate your work.

In the sewing industry, allowances vary according to the seam location and type. The purpose of these different widths is to make construction efficient and yield a sturdy garment with the proper structure and drape. Home sewers can easily adapt commercial patterns to these same standards. Most commonly, seam allowances need to be reduced in width. Narrower seam allowances save time and fabric, because you don’t waste yardage on larger pattern pieces or spend time trimming the unneeded allowances. It is also easier to sew “on gauge,” that is, accurately along the seamline. Finally, narrower seam allowances are neater and less bulky within the garment.

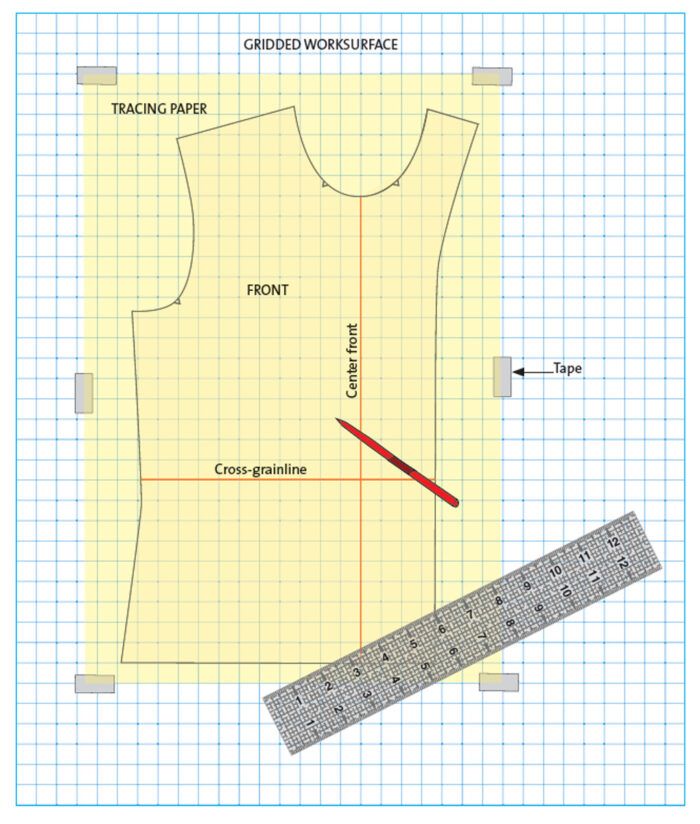

I’ll share the guidelines I use as a production patternmaker and show you how to revise your patterns with precision. My example is a basic blouse with a cut-on front facing, but the same process works for any pattern you adjust. Bear in mind that you should fit the pattern first, as these allowances may not be wide enough for significant fit-while-you-sew adjustments. Once you’ve…

Start your 14-day FREE trial to access this story.

Start your FREE trial today and get instant access to this article plus access to all Threads Insider content.

Start Your Free TrialAlready an Insider? Log in

I agree with this in principle, but this would work much easier in an industrial setting, with line production and each worker doing only one seam. Different seam allowances for different seams would be hard to keep track of for a home sewist.