READERS’ QUESTIONS – EXPERT ANSWERS

Q: What exactly is a fabric’s “hand”? Is there a scientific way to describe or quantify it?

—Natalie Burch, via email

A: The Threads editors and our staff seamstress purchase, sew with, and write about a wide range of fabrics, so we are routinely faced with talking about “hand”: A fabric’s hand (also called “handle”) is defined in Fairchild’s Dictionary of Textiles (Fairchild, 1996) as “a characteristic of fabrics that is perceived by touching, squeezing, or rubbing them.” The only thing a home sewer needs to determine the hand of a textile is their hand. For most sewers, this provides adequate information.

The vocabulary you use to describe hand can be as simple or complex as you like. Basic notions of texture—smooth, rough, fuzzy—are easy to define, as are the fundamental kinds of drape, which range from fluid, as in silk jersey, to stiff, as in heavy cotton duck. But the more specific you can be in describing a fabric you have, or one you are looking for, the more successfully you can match a fabric to the design you want to make.

Characteristics to consider when you touch a fabric include crispness, silkiness, thickness, clinginess, crushability, permeability to air, stretchiness, springiness, sponginess, wrinkle-resistance, “dryness” (a paperlike sensation when you run your fingers over the fabric), and thermal insulation or conductivity. You can also determine if a fabric is stable or unstable and, therefore, easier or more challenging to work with.

Articulating a textile’s properties can be a little like describing the flavor of wine. Discovering just the right words can increase your appreciation and may also help you decide what the item’s best use will be. If you find yourself using words like “slithery” or “tissue-like,” you can be confident that the material won’t work well for tailored trousers, for example.

For professionals in the fields of textile manufacturing, hand is an equally serious matter, and they have come up with systems and machines for evaluating and quantifying a fabric’s tactile qualities. The Kawabata Evaluation System uses a series of

instruments to analyze fabric hand. One machine tests compression and resilience, to find out how much a fabric can be flattened, and how well it recovers its original thickness.

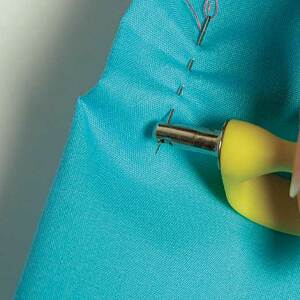

Another measures the amount of force required to bend the fabric, to determine stiffness. There’s a device that tests roughness by finding the coefficient of friction of a fabric’s surface, and measures the depth of any surface texture. In shear testing, woven fabric samples are pulled diagonally by parallel bars to find out how easily the fibers can be pulled off grain; this corresponds to drapiness and bias give.

Simpler mechanisms for testing hand include measuring the force required to push a fabric through a narrow slit. Another approach measures the resistance when the sample is pulled through a round aperture. There are systems that can tell a manufacturer how various finishing processes, or even repeated laundering, will affect the sensory qualities of a fabric.

Thus, there are scientific methods for evaluating and describing a fabric’s hand. However, because sewing and wearing a textile are subjective experiences, your own study of a fabric’s hand is much more meaningful.

This post was originally featured in the Q&A department of Threads #214 (April/May 2021).

Have a Question? Send it to us and we’ll find an expert’s answer.

via mail: Threads Q&A, PO Box 5506, Newtown, CT 06470-5506

via email: ThreadsQ&[email protected]

via the Contact the staff page to submit your entry

Log in or create an account to post a comment.

Sign up Log in