Learn to Make a Scarf with a Serger: Make Fabric from Thread

Thread, soluble stabilizer, and a serger are all you need

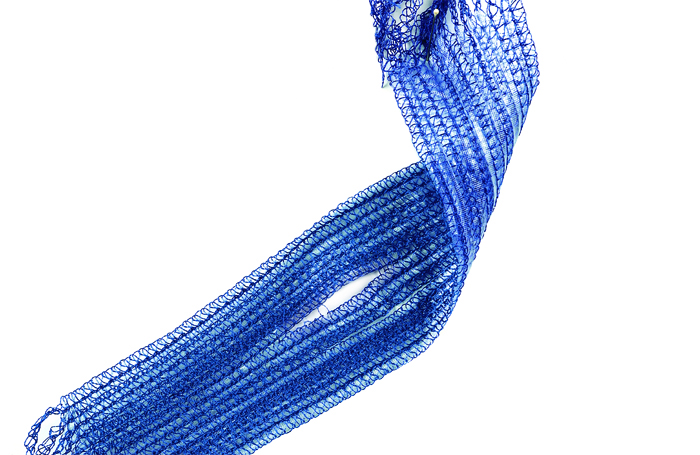

It never occurred to me when I bought my first serger 21 years ago that someday I’d use it as a knitting machine and make my own fabric. But that’s what happened with the scarves shown. Slightly overlapped rows of three-thread overlock stitches create this stunning fabric and the fringe to go with it.

As with all creative projects—or processes—you need to spend some time exploring the possibilities. The basics are simple. I’ll tell you how to set up your serger, stitch over water-soluble stabilizer, fix imperfections, rinse out the stabilizer, and finish your scarf. I’ve sewn quite a few of these scarves, and each one takes about two hours to make.

Any thread will do

One scarf takes approximately 850 yards of thread, and the ones you use will establish the nature of your fabric, texture, color, and pattern. Multiple colors create varying effects depending on how each color is threaded—in the upper and lower loopers and in the needle—and the direction in which it’s sewn. Try experimenting with your leftover spools of thread.

If you use one color in the upper looper and another in the lower looper and stitch constantly with the same side facing up, you’ll achieve a different color on each side. If you flip your work at specific intervals, you can achieve a striped effect. Thread your machine with one type and color of thread, combine different thread weights and fibers to change the fabric texture, and change colors randomly or at measured intervals to create stripes.

If you try using two threads in each looper, use a separate thread stand for your needle thread and the four built-in thread spindles for your loopers. Threads or yarns that are too thick for the eye of the needle will often work in the serger loopers.

Serge and stabilize

Thread your machine, and set up a three-thread overlock stitch with the widest and longest stitch length and the needle positioned in the left side. I generally set the needle tension much lower than the looper tensions. Adjust tensions until they’re to your liking. If the needle thread draws up too much when stitching, reduce its tension.

Use water-soluble stabilizer

Cut water-soluble stabilizer into 1-inch-wide strips. Cut one strip as long as the desired scarf length. This is the first strip you stitch—the other strips can be cut to length or overlapped as you sew. By the time you finish stitching your scarf, you’ll have quite a buildup of stabilizer, but it will disappear in the wash.

Overlap your stitching

Sew slowly, especially if you’re using thicker decorative threads in the loopers. Listen to your machine. This sewing is unusual because fabric isn’t involved. You can usually hear when a threading problem arises because your machine will make a different sound just before the threads break.

Hold the thread tails taut as you start to sew, and sew a chain a few inches long for fringe. Slip a stabilizer strip under the foot, and stitch along the length of the strip, trimming off a sliver of the stabilizer. When the desired length is sewn, stitch off the end of the stabilizer, and sew a free chain at least twice the length of the first chain; these chains become the fringe. Cut the chain in half to free the strip.

Turn the stitched strip around, and stitch down the other side, catching the previous row of stitching with the serger needle as the knives trim off the excess stabilizer. Repeat, as before, making the fringe. Keep your fringe tails away from the knives so they don’t get cut off.

Center a second stabilizer strip under the previous strip and stitch again, catching the stitching on the left and trimming the excess stabilizer on the right. Chain off for fringe, as before, and turn the strip around to sew the next row. At this point, you’ve connected four rows of stitching and used two strips of stabilizer.

Keep the stabilizer to the right side of your sewn strip, by adding a new strip of stabilizer, stitching, and trimming as before; then fold the stabilizer out to the right from under your stitching to stitch again. Each strip of stabilizer is sewn twice as you add stitching rows.

Repeat the above steps until you reach the desired width. At this point, I like to raise my serger knife blade and sew a second row of stitching on top of the last row on each outer edge to strengthen and better stabilize the two edges. When the stabilizer is dissolved, the scarf shrinks in length and width a variable amount, depending on thread, tension, settings, and other elements.

Check your work before dissolving the stabilizer

Look for gaps where the needle failed to connect the stitched rows by holding the scarf up to the light.

Mend the gaps with matching thread and a loose-tension zigzag stitch on your sewing machine. To mend invisibly, knot the thread and bury the tails. After you’ve mended the holes, you can add decorative stitching by hand or using your sewing machine.

Even up the fringe lengths (or not), tie knots in the ends, or add beads to the fringe before knotting it.

Rinse and dry

Soak and rinse your scarf multiple times to remove all traces of the stabilizer. Wrap the scarf in a towel to absorb excess water, then dry the scarf flat.

When your scarf is dry, hold it up to the light one last time and pull the side edges outward, looking for holes. Don’t be surprised if you missed finding a few holes. They can be loosely and invisibly whipstitched by hand to close—or become a design opportunity for adding beads or tying shut with ribbon.

This article, by Karen Tornow, was published in Threads #123 (Feb./March 2006). Photos by Sloan Howard.

Brilliant idea..