What Kind of Serger is Right for You?

They all trim , overcast, and sew a seam quickly, but some do much more.

Sergers are basic equipment in sewing rooms and garment factories around the world for one reason: They can trim, overcast, and sew a seam all in one pass – all while stitching at twice the speed of a regular sewing machine. Perfectly suited to any knit or woven, stretchy or ravel-prone fabric, serged seams are everywhere, from T-shirts, swimsuits, and jeans to high-end designer sportswear and eveningwear. Sheer scarves, canvas drop cloths, and elegant table linens may all have serged edges, and even lingerie depends on the tiny seams and soft elastic insertions possible with sergers.

Sergers are sometimes called overlock machines, but to avoid confusion in this article, when the word overlock is used, it is referring to a particular stitch rather than the machine.

A knife, needles, and loopers create an overcast seam

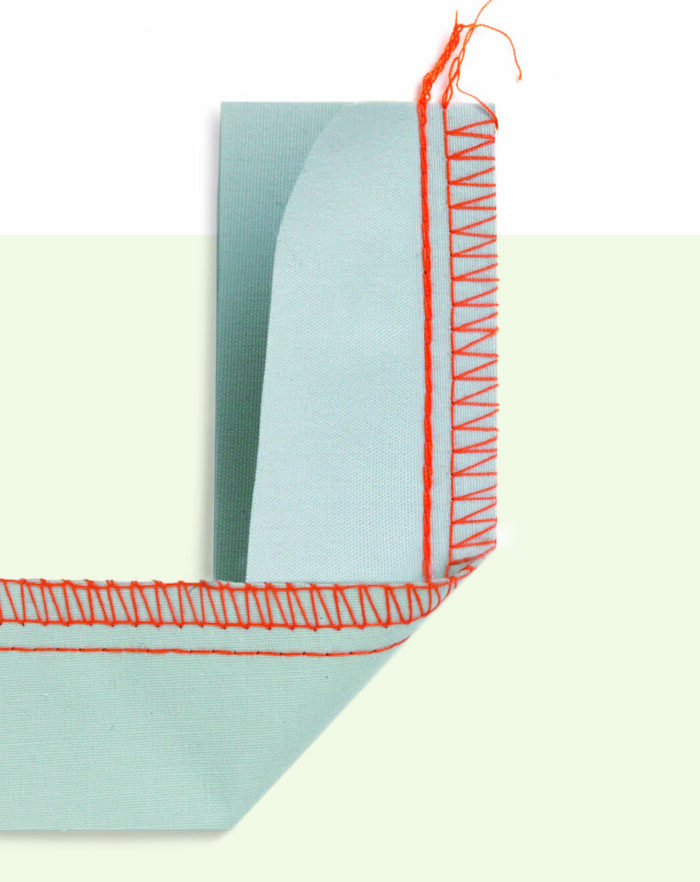

All sergers have at least one needle and two loopers; the latter are moving metal arms, which have an eye that carries thread but doesn’t penetrate the fabric. The stitch all sergers have in common is the 3-thread overlock. Before the stitch is formed, the fabric is drawn under the presser foot by the feed dogs, where a moving knife parallel to the presser foot trims the seam allowance edge an instant before the stitching starts. Two loopers then overcast the edge, knitting their threads around a metal stitch finger (which keeps the fabric edge from collapsing), to create a binding that is immediately secured as the needle sews what looks like a straight stitch. A 4-thread overlock has a second, reinforcing, “straight” stitch, which is added simultaneously by a second needle. If you feed two layers of fabric through a serger at one time, they will be joined by one or two seams (depending on the number of needles) and the seam allowance edges will be overcast together and cannot be pressed open.

Most sergers sew a variety of stitches in addition to the overlock. Each model’s versatility is established by the number of threads it can handle, presser feet available, and the options for adjusting needle and knife positions, looper function, feed dog speed, thread tension, and threading paths. For each stitch, the user adjusts these items in a manner indicated in the operating manual. Subtle adjustments to the setup of the basic stitches produce a variety of seam, hem, and embellishment options.

A 2/3/4/5 serger? What do all those numerals mean?

Serger models are often described by a string of numbers and slashes. This countdown informs you that the machine can sew specific stitches, all of which are described in “Six utilitarian stitches to consider” (below). Serger savvy sewers know, for example, that a 2/3/4/5 machine can make all the basic serger stitches that call for two to five threads. The 2/ means the serger will sew a 2-thread overedge stitch; thus if a serger is identified as a 3/4/5 machine, it cannot make a 2-thread stitch. A 3/4 signifies a serger’s ability to sew the basic 3- and 4-thread overlock stitches. The 2/ overedge and 3/ overlock stitches can be adjusted to be flatlock stitches. The 5/ indicates that the machine also sews a chain stitch; this 2-thread seaming stitch can be used alone, but when combined with the 3-thread overlock, it makes a 5-thread safety stitch.

Uses beyond edge finishing

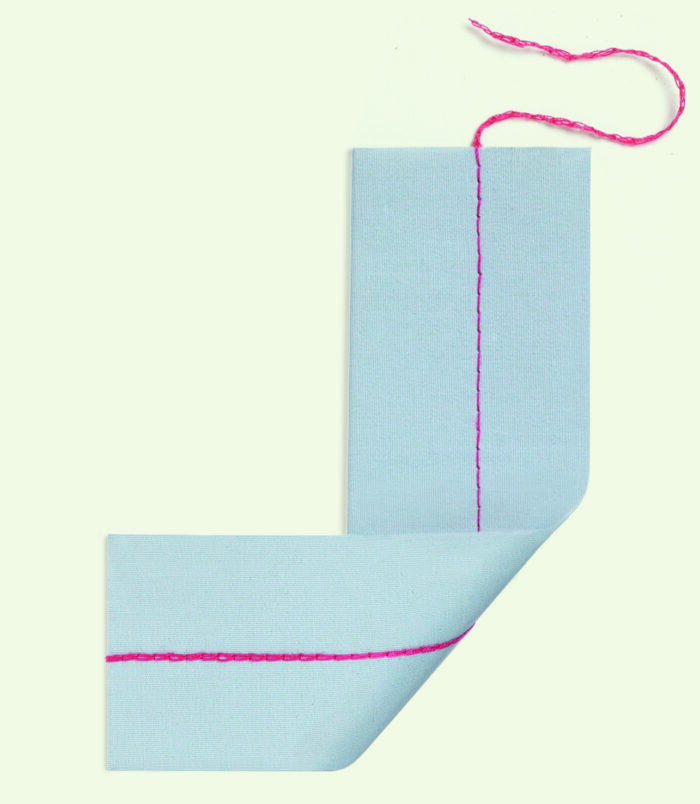

Over the last couple of decades, as the serger became evermore popular, a variety of stitches were developed for it, and its use is no longer limited to edge-finishing and seams. The knife can be disengaged so the machine can sew without first cutting the fabric, making it possible to place the stitches at a distance from the fabric edge-useful for the chain stitch and necessary for the cover stitch (a stitch for hemming available on some sergers). Some operations, such as the overedge stitch or rolled and blindhem adjustments, finish an edge but do not simultaneously sew a seam. The serger can even be used to create embellishment, using flatlock stitches, chain stitches, and cover stitches. The cover stitch is often seen on ready-to-wear; from the top it appears as two rows of parallel stitches, on the reverse it encases the raw edge of the hem with interlooping threads. Some machines offer a variety of cover-stitch styles that are equally handsome on both sides of the fabric for reversible applications or various embellishment effects. If you’re happy with your present serger but want to add a cover stitch, consider purchasing a single-purpose coverstitch machine, which is a cousin to a serger.

Features that ease enhance serger sewing

Features that ease enhance serger sewing

Engineers continue to add bells and whistles to the basic serger. These either simplify setup and operation, or expand the stitching functions. Things to look for:

Differential feed

Once an optional feature, differential feed is now seen on the majority of machines at every price level. Its function is to adjust the way fabric is fed under the needle and thus to ensure a smooth, pucker-free seam on various fabrics. This is accomplished with two sets of feed dogs, one in front of the other. By changing the speed of the front feed dogs you can produce a stitch that’s slightly gathered (eased) or slightly stretched. This feature is also used to intentionally stretch or gather fabric for decorative purposes, as for a lettuce edge-a rippling, ruffled effect created when the stitches keep an intentionally stretched edge from relaxing.

Threading ease

Sergers have a reputation for being hard to thread. The loopers are awkward, with eyes at difficult angles, and must usually be threaded in a specific sequence to prevent the threads from tangling.

Many models offer easy-threading features: Snap-on and swing-out presser feet and tilting needle clamps make it easier to get to the needle. Color-coded threading paths and charts printed on the machine remind you how to thread so you don’t have to refer to the manual. Needle threaders, self-threading loopers, and air-jet threading make threading a snap; and tubular, thread-encasing loopers can be threaded in any sequence. These features greatly simplify threading, but they are a luxury that does raise the price.

Tension adjustment

Setting multiple thread tensions to achieve a balanced stitch on a serger is more complex than setting the single tension on a standard sewing machine. Additionally, different stitches can be sewn when the thread tensions are altered, so users may change the settings often and sometimes drastically. While tension adjusting is not hard, the automatic and self-adjusting tension settings available on some machines virtually eliminate confusion. Some models set tensions automatically; others use a chart or an LCD to direct you to recommended settings. On a few sergers, tension dials have disappeared altogether because the automatic adjustments work so well.

Embellishment applications

Specialty feet are available for embellishment or trimming techniques such as fagoting, felling, or attaching lace or beads, and for specialized tasks like making pintucks and belt loops. Yarns and ribbons can be threaded through loopers easily for decorative stitching and since they are fed from spools, they won’t run out as they would on a bobbin.

Known as the microwave of the sewing room

A serger will never replace the sewing machine: It doesn’t sew into tight curves very well, the space to the right of the needle is limited for projects that extend in that direction, and it only stitches forward. But even the most feature-lean model can save you hours on your projects.

Six utilitarian stitches to consider

Each of these six stitches makes a different kind of seam, and together, they form the basis of all enhanced serger sewing. But not all sergers can sew all six-before choosing a model, decide which stitches are essential for you.

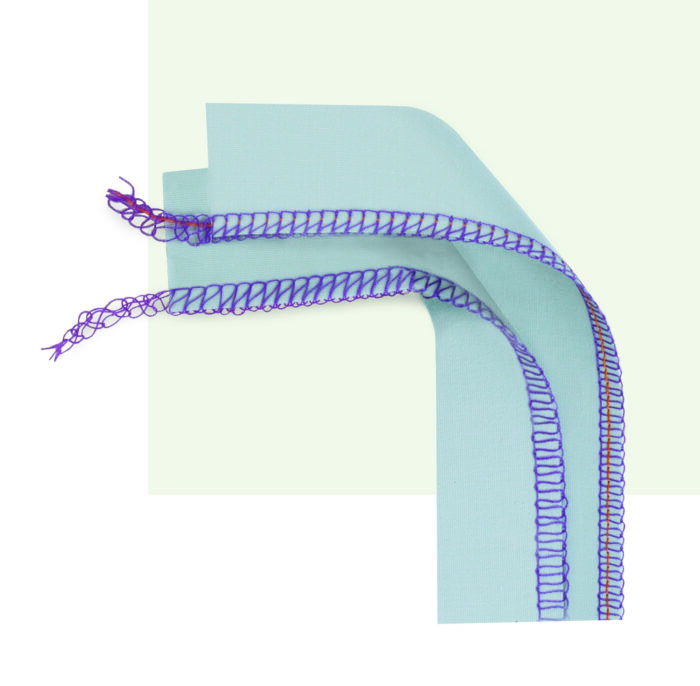

Overlock Stitch

The 3-thread overlock is the basic serger stitch. It is made with a single needle thread and two looper threads. It is used to sew seams and simultaneously overcast the seam allowance, and it has moderate strength and stretch-ideal for T- shirts or loose-fitting garments and those made from lightweight woven fabrics. It is also used to overcast the raw edge of a single layer of fabric. If the tension settings are adjusted, this stitch will create a narrow rolled edge or a flatlock seam.

The 3-thread overlock is the basic serger stitch. It is made with a single needle thread and two looper threads. It is used to sew seams and simultaneously overcast the seam allowance, and it has moderate strength and stretch-ideal for T- shirts or loose-fitting garments and those made from lightweight woven fabrics. It is also used to overcast the raw edge of a single layer of fabric. If the tension settings are adjusted, this stitch will create a narrow rolled edge or a flatlock seam.

A second needle and fourth thread add a second row of straight stitches to create the 4-th read overlock, which

produces a stronger seam appropriate for heavy fabrics, like denim, or areas that receive stress.

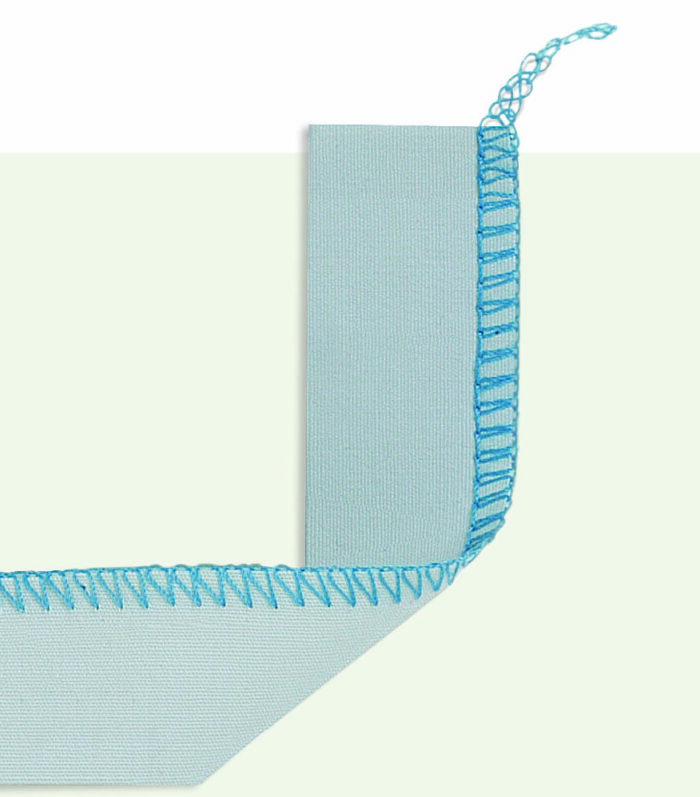

2-Thread Overedge Stitch

When the machine is set to this stitch, the upper looper is converted to a hook that pulls the needle thread into an interlocking pattern with the lower looper thread, Too stretchy to make a good seam, a 2-thread overedge binds the edges of lightweight fabrics beautifully, can be used to sew a stretch blind hem for knits, and will create a fine rolled edge.

Flatlock Stitch

Used on sporty clothes where you want the seam allowance felled (stitched flat to the garment instead of hanging loose from it), a flatlock stitch is achieved by loosening the needle tension of a 2-thread overedge or 3-thread overlock stitch, To use it, sew two layers of fabric, wrong sides together, and then lift one away from the other, The seam allowance will fold against the fabric on one side, inside the threads, and a thread ladder will form across the seam on the other side. This stitch makes an interesting embellishment when it is sewn on a folded edge with decorative threads in the looper.

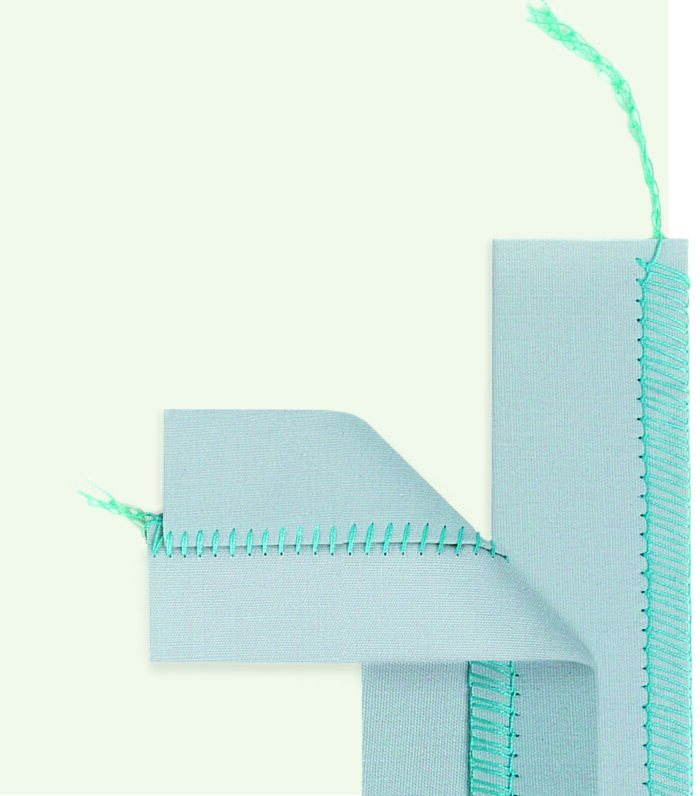

2-Thread Chain Stitch

This stitch looks like a straight stitch on top of the fabric and a thicker straight stitch on the bottom. On closer examination, the thickness on the bottom comes from the thread looping back three times for each stitch. Rarely used for knits because it has little or no stretch, it is often used on woven fabrics for seams (often in combination with an overlock stitch), or with the knife disengaged and sewn with the fabric wrong side up, for decorative topstitching. When elastic thread is used in the looper the stitch creates shirring. If the lower thread is pulled, the stitch will instantly unravel so it makes a good basting stitch.

5-Thread Safety Stitch

A 5-thread serger can be set to simultaneously sew a 2-thread chain stitch and a 3-thread overlock stitch. This combination is commonly called a 5-thread safety stitch; it is stable, nonstretching, and appropriate for use on woven fabrics.

Cover Stitch

When made with the knife disengaged, this stitch can be used to secure a hem of any depth. The two needle threads form parallel lines on the top of the fabric and the threads in one or more loopers form a braided or overcast pattern on the bottom. The braided side of the stitch covers the raw edge of the folded-back hem allowance. For an attractive embellishment, place decorative thread or yarn in the loopers and sew with the fabric wrong side up. Sophisticated machines offer more cover-stitch options with various stitch patterns; some sergers will take a twin needle, which will add a third row of topstitching.

Match Serger Capabilities to Your Sewing Projects

Quick clothes

You’ll fancy a 3/4/5 serger with differential feed if you like to sew easy sporty patterns in knits and wovens. Besides the workhorse seams made by the stitches on this type of machine, you’ll want the easy elastic application it offers. Extras to consider include heavy-duty knives for denim, and cover-stitch capabilities for hems.

Lingerie and activewear

You’ll need a 2/3/4 serger with differential feed to sew the special fabrics in leotards, swimsuits, sweater knits, and lingerie, make fine bound seams on delicate knits, and reversible, bulk-free flatlock seams. This type of serger covers the bases for stretch blind hems, stretch seams, 2-thread flatlock for lace insertion, and rolled hems. If your projects include embellishment, special feet for applying pearls or cording are available.

Tailoring and haute couture

A 2/3/4/5 serger with differential feed provides 2-thread overedge finishes for seam and hem allowances, chain stitches for basting, and overlock stitches for seams on linings. If you sew eveningwear or do fine dressmaking, you’ll want good rolled hem options too.

Home decorating

A 3/4/5 serger with differential feed provides fast, sturdy seams and rolled edges for fabric of all weights-important in this category, where projects are large and fabrics range from heavy upholstery weight to sheer panels for windows and include all sorts of table or bed linens, all with edges that tend to ravel. Specialty feet for shirring, gathering, and cording are options to consider.

Embellishment

Any 3/4/5 serger will open a world of possibilities if your interest lies in adding surface embellishments such as abstract topstitching and couched or braidlike trims. You can feed exotic threads, ribbons, and yarns, through the loopers, use flatlock stitches for couching or braided effects and for piecing fabrics, and chain-stitch free motion designs. Specialty feet for applying pearls or cording and easy threading are the luxury features for this sewing category.

Log in or create an account to post a comment.

Sign up Log in