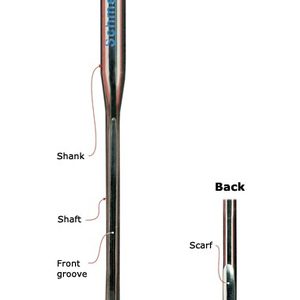

Compare the size of your thread to the size of the groove that runs down the needle to the eye. If the groove cradles the thread you should have trouble-free sewing.

Whatever sewing machine you use, it won’t work right without three essential elements: the thread, the needle, and you. Obviously, you drive the whole sewing operation, but you’re also the indispensable match maker for the needle and thread marriage.

For example, you try, on various levels, to match your thread and fabric—getting the right color and the best fiber combination for starters. But, have you noticed, especially if you sew with a variety of fabrics, you can’t find thread in the same fibers as some of your favorite fabrics, such as wool, linen, spandex, or hemp? For practical purposes there are four thread fibers you can use for construction sewing: polyester, cotton, silk, and nylon. Polyester is a great all purpose thread. I’ve stopped using cotton thread because it leaves so much cotton fuzz in my machine, silk thread comes in several machine-worthy weights and always sews beautifully because it is clean and smooth, and nylon is strong for upholstery and outdoor gear but not hot iron heat.

That said, the most important choice is getting the right needle/thread combination. The needle points are designed for the fabric, but the eye is designed for the thread, and the groove is designed for the size of the thread. You may not realize that a thread passes through the eye of the needle 30 to 50 times before it’s stitched into the fabric. The wrong shaped eye can cause the thread to shred or fray or skip stitches. So when you’re sewing with specialty or novelty threads you’ll have the best success with a specialized needle—use a Metallica needle when using metal threads for example.

Needle manufacturers recommend changing a needle after eight hours of use. This does not include the cutting, pressing, and the fitting time that goes into completing a project. I’ve never put it to a stopwatch, but I don’t spend an hour of sewing on any basic garment. At that rate I could sew eight projects before replacing a needle. In the interest of the environment and avoidable waste, use common sense—a trench coat with a lining, twelve button holes, belt loops, and multiple flaps, or a large project like a quilt will take more sewing time…but don’t throw away your needles before their time.

there's a "Metallica" needle??? Lol. They were my favorite band when I was a kid. I didn't know they ventured into sewing! Ya lost me on that.

by golly there is. I just did a google search. I will have to get some of those now (because I have metallic thread!! I just can't get away from metal ;))

I am far from any type of needle mechanic. in fact even sewing. I did have a question though. Yes, even this old man watches Nancy on my local TV station. I 'think' she uses a lightweight thread for the bobbin at least sometimes.

I am on a fixed income and thread costs about it's weight in gold these days. Silk thread? You have to be kidding?

Anyway, you mentioned thread weight to needle opening. How do you size a needel to the thread AND the bobbin thread.

My projects are not forever.. Just in the home. I try to use that miles of thread for a reasonable price in my bobbin. I hate it when the thread runs out in th middle of a job and I never noticed it happening. I try to use 'SureLock' spun Polyester for overlock machines in my bobbin. The other thread may be a bit different. I have no idea what a overlock machine is.

I will have to respectfully disagree about cotton thread and its use. You say you don't use it? It fuzzes up your machine? As a sewer and quilter, I use a lot of cotton thread. I make every attempt to match the thread to the fabric. With quilts this is especially important as over the years, the polyester thread can actually cut the cotton cloth and you end up with a quilt in shreds. I have switched almost exclusively to Presencia thread as it does not fuzz up my machine. I also clean out my machine on a regular basis which is a very easy task with my Bernina. I agree the right needle is essential, but the right thread for the job is too.

WillGeorge, An Overlock is also called a serger. It is known for cutting and sewing at the same time. It typically uses 3 and 4 spools of thread at a time. This being said, most often the thread for these machines isn't as strong, and a lot of times is not appropriate for use in your utility sewing machine.

A lot of needles are packaged with recommendations for use on certain fabrics and threads. The staff at a lot of fabric stores can be very helpful in matching your project, with appropriate fabric, thread, and needles.

LindaJCasey, I agree with your assesment on thread. I do more garment sewing, and try to match thread content with fabric content. Silk thread has been known to cut fabric at times as well.

I do have a question to the author of this article, If the thread is properly chosen for the fabric, and the needle is properly chosen for the fabric weight and content, will It not also be right for the thread? With the exception of embroidery and metelic?

Perhaps I have been lucky so far, but I have found so far that matching everything up this way has worked. Is there a test to determine that your thread and needle are made for each other?

Janeaneasley

Thank you for the reply.

You suggested to talk to the store staff. LOL.. The women mostly think I am a nut walking in off the street. At my old age I would guess I should shave for the visit? They were different when I walked in with my little China girls. Alone, a different story!

I am OK with that. I always told my three daughters not to talk with strange men!

I got some VERY expensive cloth from Japan (not silk but very smooth, sort of like silk) Dumb me... I threw away the tag that said what material was.

I made my two China little girls a Chinese style poster bed for each. (I am a woodworker) The fabric with lots of dragons, they picked out at the store where I got the fabric. They are only five years old but who am I to argue with a woman...

I used some purple sort of matching color thread and the serger thread (sort of the same color) for the bobbin. I was wondering if I need to stitch again with something else? This cloth is the top of the canopy and will need occasional washing?

I see no way to post a picture of the fabric. Not sure if I still have the picture.

Janeaneasley

My second sewing machine job in my life..I bought a sort of inexpensive Singer Inspiration for this job and then gave it away to the Purple Heart folks... Do I really need to buy another machine to make it right?

I have had trouble sewing the synthetic knits, especially the type with the printed "sequins." I have tried all types of needles and threads but I still end up with skipped stitches. Any advice?

Right needle for fusible tricot interfaced natural fiber woven fabrics?

I'm working on garments made of medium weight wovens (cotton and rough silk kimono fabric) with facings & collars interfaced with fusible tricot knit. I'm finding the stitch quality to be a bit "swervy" and suspect I don't have a good match of needle to the fusible tricot interfacing.

I'd love to have your recommendations for proper needles to solve this problem. (Due to experimentation I'm fairly certain the problem isn't caused by thread type, dull needle, stitch length etc.)

Thanks in advance!

Sometimes picking out the right needle and thread combination can take some trial and error. I have the most difficulty with synthetic knits. Sometimes a universal will work better than a ball point needle. I just have to try until it looks good. There are a number of sites that will help to start your needle vs. thread match. http://www.coatsandclark.com/Products/Sewing/Threads/Dual+Duty+XP/XP+Thread+Advisor.htm is the Coats & Clark site. I have even e-mailed manufactures for advice. Some of it has been extremely helpful. Mettler thread is available in my area. I do not use it a lot so their web site http://www.amefird.com/mettler.htm has been helpful for me to understand their thread.

I sew with a variety of fabrics and I am always changing needles. I try to use my needles till they die. By die, I mean the tip will dull or bend just enough to skip or wobble a stitch on one of my big projects. To look at them they look fine. Before I do trash a needle I will use a product called Innovations Needle Release, From Stan Rising CO., Inc. or All Purpose Sewers Aid, W. H. Collins Inc. I think they are both silicone based products. I use them very sparingly and have never seen any long term problems with them. I will even wipe a needle with rubbing alcohol to remove any residue they may have picked up. When sewing on very expensive or exclusive fabrics, very fine silk, or some ribbons, the cost of throwing out a needle is trivial. I will either set it aside to use latter or throw it out.

I also do a lot of quilting and use nothng but cotton thread. And since I use a LOT of thread (white or natural) I look for sales as I can go through a large spool of thread in two weeks. I have found that the cheaper thread (2 spools for $3.00) will fuzz up terribly. But even the same brand but not on a special promotion works find. Fortunately because I sew so much, I clean my machine every Saturday morning - I have a dandy little vacuum. A lot of fuzz can be a disaster for the machine.

The groove in the needle is also used to insert the tip of the thread into the groove and gradually slide it down to the eye of the needle for easy insertion through the eye of the needle. Two index fingers may be required to hold the thread in place as you slide it into place. A quilter taught me this technique. I am Transylvania as I can't tell you how many sewing machines I have worn out, and honestly some of my projects have been quiet frighting. I suggest you always pick out your pattern first before picking out your fabric, or you too will learn the hard way as I did by buying multi-colored, small-plaid fabric followed by buying a Vogue Couture pattern with umpteen vertical seams--it was a true engineering feat--but the mission was successfully accomplished after many hours of thought and preparation.

I have never done that to myself since, but don't we all learn the hard way?

OK, I was always taught to match your thread fiber to your fabric. Cotton thread to cotton fabric, silk thread to silk fabric, and poly to poly, etc. Also that most American made threads are made wound to the right and therefore that is the cause of most of the lint build up in machines (and fuzzy fabrics) whereas European threads are wound to the left and spool through the machines to the left causing less lint. You can feel the difference in the short spun fibers of the American made threads vs the European made threads if you run your fingers down the length of them. I too agree with lindacasey about putting poly threads on a cotton project---bad idea. It will get cut up over time.

As for the needle, my experience has been that on most everyday woven projects a good Schmetz Universal 80/12 needle is great. They have wonderful training resources too to educate about all kinds of needles for different uses. Even metallica!

Because I own an old Singer Industrial sewing machine: Model 31-19 and I restored and repaired it myself. I was looking for info on matching needles and threads; I chanced upon your article. I enjoyed reading this article on "Needle Me: Pick the right needle and thread" as well as all the comments. I also bought my wife a Singer Quantum Stylist 9960. It seems my wife wants to sew but don't want to read; so I end up reading, choosing needles, winding the bobbin and threading the needles.

My interests are everything that has to do with machines, computers, electronics,

carpentry, plumbing and electricity, construction and because of my wife----now sewing and all the technicalities about sewing. Thanks and God bless you all.